Lightweight Materials and Structure jointly developed with SAIC VW. Successfully applied to SAIC Volkswagen, FAW-Volkswagen, FAW Hongqi, Chery Jaguar Land Rover, SAIC-GM-Wuling and other OEMs projects.

1.What’s the problem?

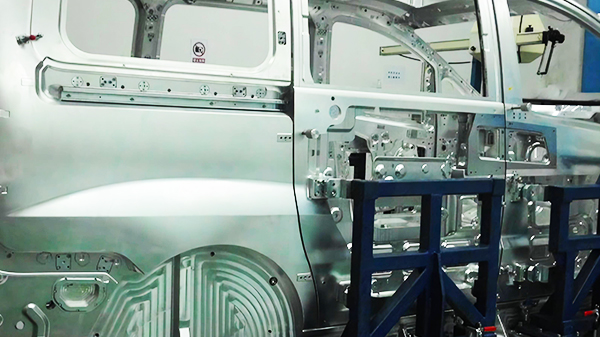

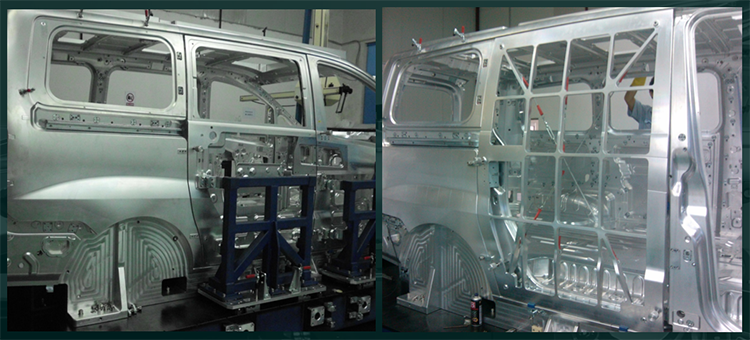

Nominal Sliding Door

Due to the heavy weight of Nominal Door, It is difficult to simulate and validate the physical door closing status.

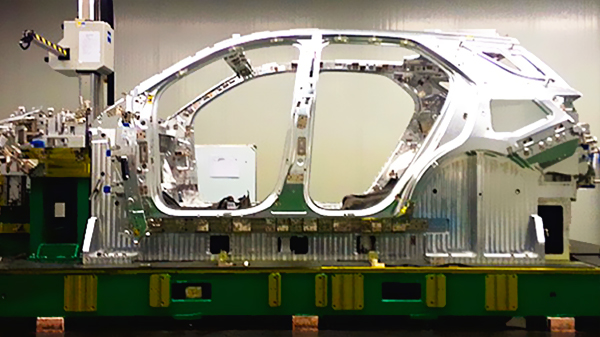

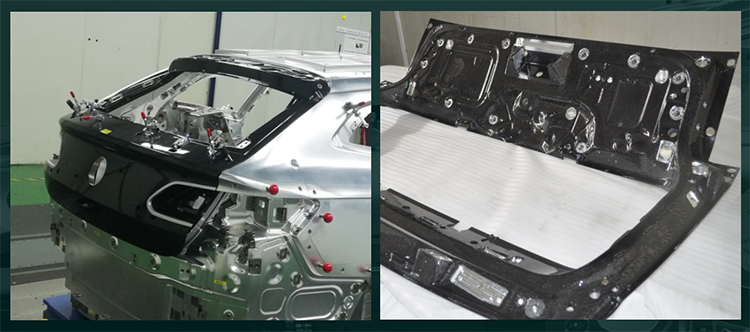

Nominal Decklid for Sedan or Coupe

Due to the heavy weight of Nominal Door, It is hard to simulate and validate the physical door closing status.

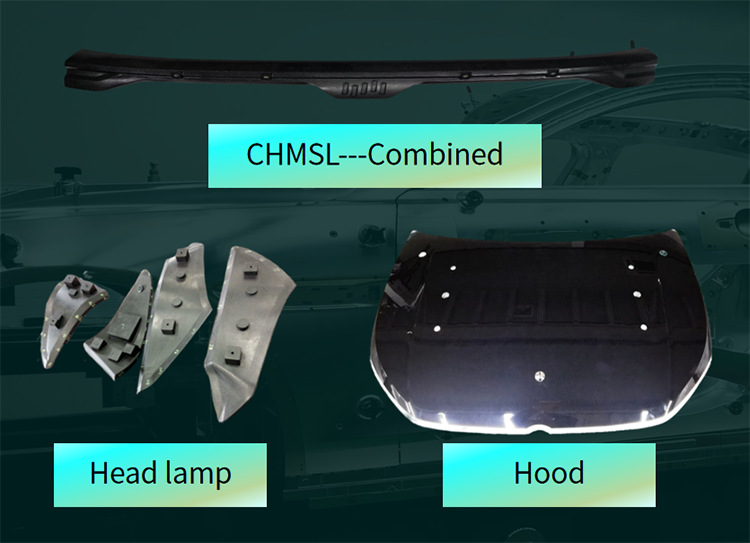

Nominal Lamp

Due to high-frequency installation and removal, the Nominal lamp needs to be lightweight.

Nominal lamp can be assembled into BIW to validate the accuracy of BIW.

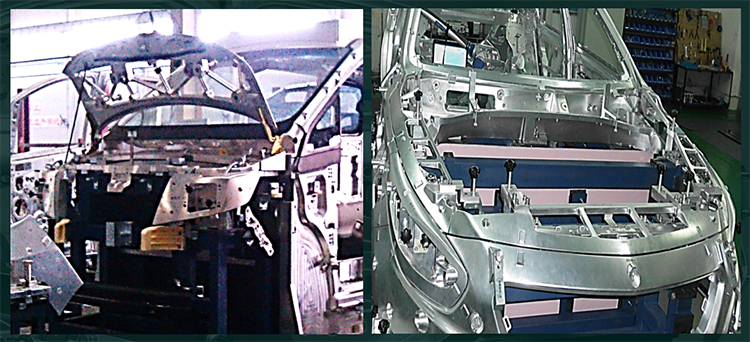

Nominal Hood

Due to the heavy weight of integral nominal hood, it is very inconvenient to open and close the nominal hood.

If with the multi-segment nominal hood, it is challenging to validate the hinge and latch matching status.

2.Lightweight Materials and Technical Features

Carbon Fiber

-High strength, high hardness.

-The same cavity structure as the actual door, can be installed door accessories such as glass lifting system, horn etc.

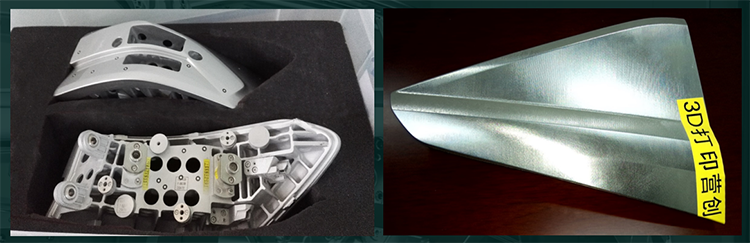

3D Printing

-SLS or SLA manufacturing, material similar to ABS or Nylon.

-SLS or SLA manufacturing, specified AL grade, high strength.

-Fast Production

3.Case Study

3D Printing

As heavy as the physical lamp,Ergonomic Optimal Replacing for OCF in BIW ,The short manufacturing period and suitable for design changes,Jointly developed with SAIC VW.

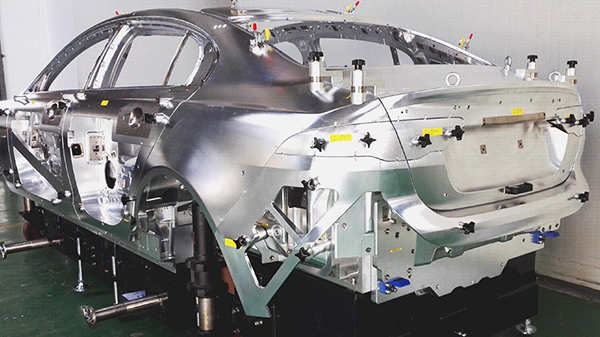

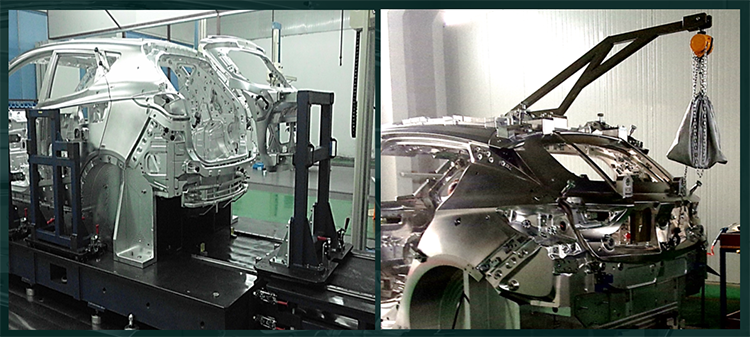

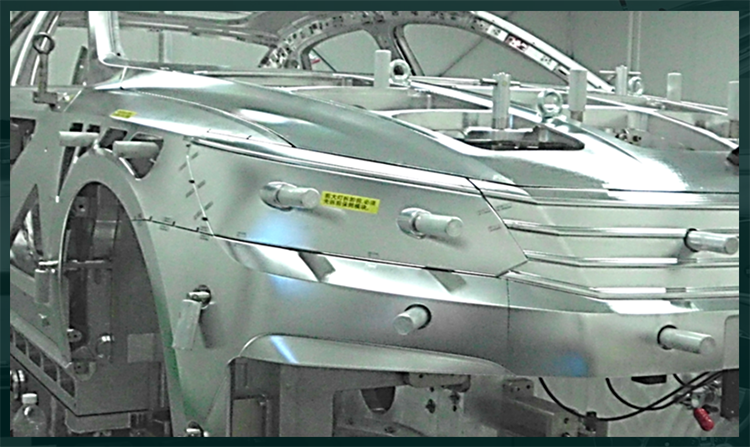

Carbon fiber

As heavy as the physical door.

Jointly developed with SAIC VW.

SAIC VW Annual Technology Excellence Award 2018.

Volkswagen Asia Pacific 2018 Technical Exhibition (Beijing).

SAIC GROUP “TECH-SHOW” in 2019.

Lightweight materials---Carbon fiber

Follow the request of Ergonomic.Optimal Replacing for OCF.

With high strength and high hardness, protecting for crash damage.

PROS is a leader in the field of automotive dimensional engineering technology, specializing in design & manufacturing of Cubing, Meisterbock, PCF, holding fixture, parts gauge etc.